Our Products

Silos & Storage Solutions

RMC Silos (Ready Mix Concrete)

Capacity: 50M³ to 200M³

Types: Double Cone, Bolt Nut, Horizontal Silos

Features:

Robust Construction: Made from high-tensile steel (IS 2062/GRADE-A)

Corrosion-Resistant: Powder-coated or galvanized for durability

Smooth Discharge: Anti-bridging design to prevent clogging

Customizable: Available in bolted or welded designs

AAC Silos (Autoclaved Aerated Concrete)

- Capacity: 10M³ to 500M³

- Applications: Fly ash, cement, sand storage

-

-

Features:

-

Aeration System: Ensures uniform material flow

-

Pressure Relief Valves: Prevent over-pressurization

-

Modular Design: Easy to assemble on-site

-

-

Fly Ash & Cement Storage Silos

Seamless Loading/Unloading: Equipped with rotary feeders & screw conveyors

Dust Control: Integrated bag filters & venting systems

Double Cone Silos (Ready Mix Concrete)

The Ultimate Solution for Clog-Free Discharge

Key Features:

✔ Patented Cone Design – 60° slope ensures 100% material flow without bridging

✔ Capacity Range: 50M³ – 200M³ (Custom sizes available)

✔ Construction:

Body: 6mm thick IS 2062 Grade-A steel

Cone: 8mm thick wear-resistant steel with internal vibrators (optional)

✔ Specialized Discharge System:Pneumatic/hydraulic outlet gates

Anti-segregation baffles for mix consistency

Technical Advantages:

Zero Residual Material – Unique cone geometry prevents buildup

Faster Cycle Times – 30% quicker discharge vs. flat-bottom silos

Low Maintenance – Easy-access inspection hatches

Horizontal Silos (Ready Mix Concrete)

Space-Optimized Storage for Urban Sites

Key Features:

✔ Compact Footprint – 40% smaller area than vertical silos

✔ Capacity Range: 30M³ – 150M³

✔ Modular Design:

Bolt-together sections for easy transport

Expandable with additional modules

✔ Discharge Options:Screw conveyor integration

Truck-loading chutes

Technical Advantages:

Low-Height Installation – Fits under height restrictions

Rapid Deployment – 48-hour onsite assembly

Dual Compartment Models – Store 2 materials (cement + fly ash)

Material Handling Systems

Belt Conveyors

Capacity: 60 TPH to 240 TPH

Applications: Cement, aggregates, fly ash

Key Features:

Heavy-Duty Rubber Belts: Resistant to wear & tear

Adjustable Speed: Variable frequency drive (VFD) options

Low Maintenance: Self-aligning rollers for smooth operation

Screw Conveyors

Types: U-trough, tubular, shaftless

Materials Handled: Powder, granules, bulk solids

Advantages:

Compact Design: Ideal for tight spaces

Leak-Proof: Fully enclosed for dust-free operation

Bucket Elevators

Vertical Material Transport: For grains, cement, minerals

Features:

High Lift Capacity: Up to 30 meters

Wear-Resistant Buckets: SS or polyurethane options

Silo Accessories & Safety Components

Pressure Relief Valves (VHS Series)

Function: Prevents silo over-pressurization

Standards: Compliant with ISO 9001 & ASME

Material: Aluminum/cast iron for explosion venting

Vibrating Bin Aeration Pads

Prevents Material Clogging: Ideal for cement, fly ash, powdered chemicals

Features:

Food-Grade Rubber Membrane

Low Air Consumption (1-3 bar pressure)

Twin Lobe Blowers

Oil-Free Air Supply: For pneumatic conveying

Pressure Range: 0.5 to 1 kg/cm²

Dust Collector Systems

Purpose: Efficient particulate control for silos, batching plants & industrial processes.

Key Features:

✔ High-Capacity Filtration

Filter Area: 10–500 m²

Efficiency: 99.9% for particles >5 microns

✔ Pulse-Jet Cleaning (Automatic/Manual modes)

✔ Construction:Housing: IS 2062 steel with epoxy coating

Filter Bags: Polyester/Nomex (heat-resistant)

Technical Specs:

Airflow: 500–50,000 CFM

Power: 1–50 HP

Warranty: 2 years on mechanical parts

Applications:

Cement silo venting

Industrial Hose Pipes

Purpose: Flexible material transfer for abrasives, powders & liquids.

Advantages:

✅ Kink & Twist-Resistant

✅ Static-Dissipative (for explosive environments)

✅ Quick-Coupling Options

Sizes Available: 1″ to 12″ diameter

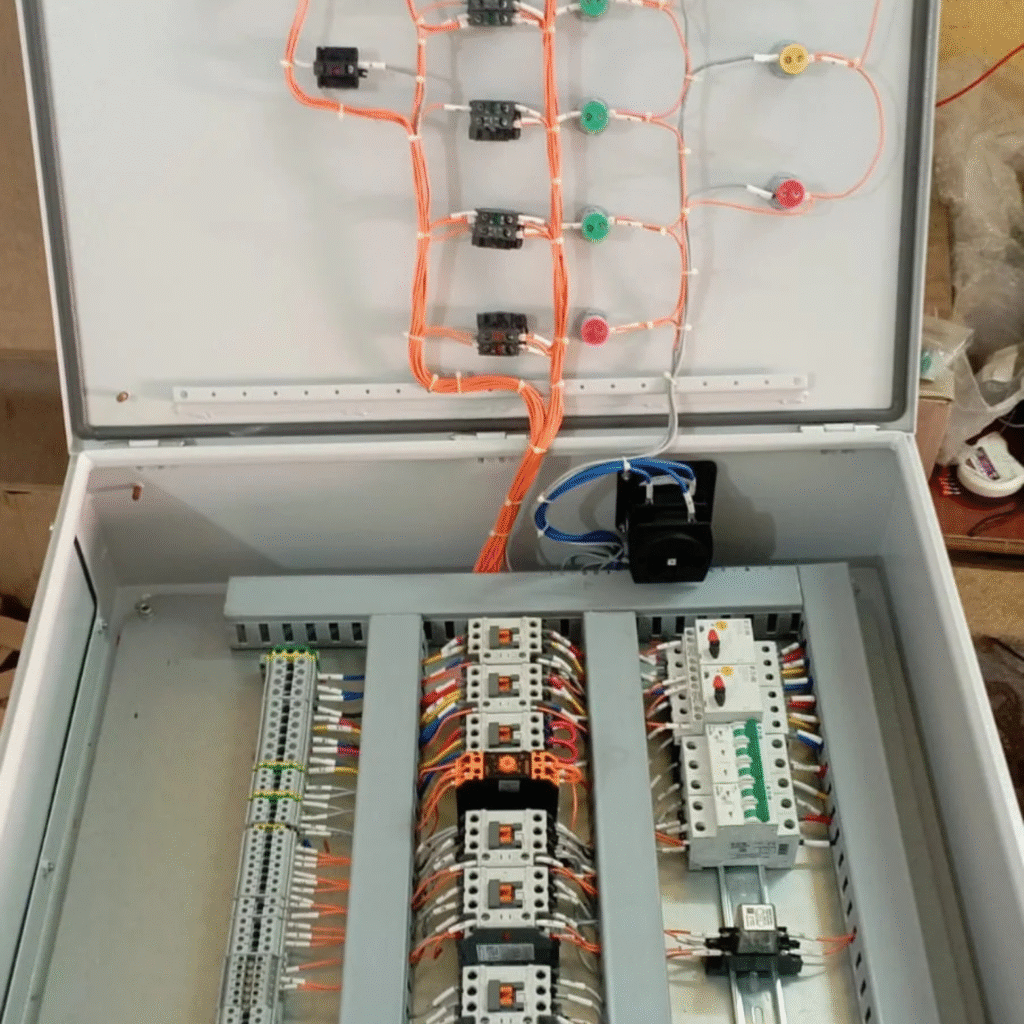

Electrical Control Panels

Purpose: Automated control for silos, conveyors & plant operations.

Panel Types:

MCC (Motor Control Center)

Starter Types: DOL/Star-Delta/Soft Start

Protection: Overload, short-circuit, phase failure

APFC (Automatic Power Factor Correction)

Capacitor Bank: 5–200 KVAR

Accuracy: ±0.95 PF maintained

AMF (Auto Mains Failure) Panels

DG Sync Time: <10 seconds

Compatibility: 50–2000 KVA generators